Frequently Asked Questions About Extractor/Dryers and Other La-Man Products

1. HOW DOES THE EXTRACTOR/DRYER® COMPARE TO OTHER FILTERS?

2. WHY INSTALL THE EXTRACTOR/DRYER AT THE POINT-OF-USE?

3. HOW FAR FROM THE POINT-OF-USE CAN THE EXTRACTOR/DRYER BE PLACED AND STILL HAVE GOOD QUALITY AIR?

4. HOW ARE THE MOISTURE AND CONTAMINANTS EXPELLED FROM THE EXTRACTOR/DRYER?

The base and chamber effectively traps moisture and contaminants as a result of the honeycomb base core. Once particles are contained in the base and chamber, they are then removed through the standard weep drain or optional automatic Float Drain. The weep drain must always remain open, as this is the only exit for moisture. The pin in the weep drain is specially designed to prevent clogging and allow the passage to be free of contaminants. Constant hissing or leakage is normal. To prevent any loss of air or noise, simply order an automatic Float Drain with your Extractor/Dryer.

5. HOW DO I SERVICE MY EXTRACTOR/DRYER?

All filters require servicing. We have designed the Extractor/Dryer to be as user friendly as possible when changing the elements. By simply removing one bolt, the unit can be completely serviced without removing it from your air line. Service Kits are complete and provide all serviceable parts needed to properly maintain the efficiency of the Extractor/Dryer.

6. IS WATER IN GAS FORM HARMFUL?

7. WHAT IS THE EFFECT OF LA-MAN AIR ON COLD DOWNSTREAM INSTRUMENTS AND PARTS?

If the temperature of the air after the Extractor/Dryer is altered significantly, condensation will occur and moisture will form. If the temperatures are cool enough, the liquids may freeze the tool during operation. In this case, the Extractor/Dryer must be installed closer to the point-of-use. If the temperature at the point-of-use is cool enough to cause condensation, this is where the Extractor/Dryer should be located. Remember the Extractor/Dryer will remove liquids & particles. It will not remove vapors.

8. HOW DOES ALL THAT WATER GET INTO MY AIR LINE?

When air is compressed, the moisture and contaminates may not compress. With 10 to 1 compression, 10 cubic feet of air, moisture and contaminates are compressed into 1 cubic foot. Because air compresses, there are now 10 times the amount of moisture and contamination in that cubic foot of air. Heat is also generated during compression. The heat will carry the moisture into the pipe system until the air has had time to cool. The moisture then condenses into liquid form; this moisture causes rust and scale. Also, if your compressor is using any oil, it gets diluted and picks up contamination as it travels down the airline. The result is ruined equipment or processes caused by wet oily air.

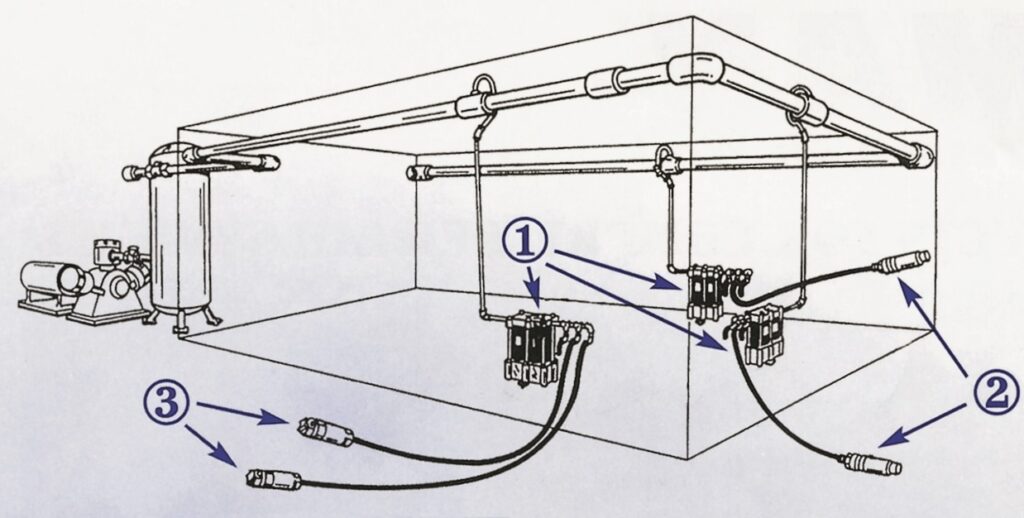

Offering a wide range of compressed air filtration products and devices, this diagram is an example of a typical installation of La-Man products.

2. Pneumatic/Dryer units installed within 6 feet of end of use for that final filtration.

3. Dryer/Pneuguard® Oiler installed to provide automatic lubrication and filtration for pneumatic tools.