Inline Pneumatic Dryers

Maintaining your compressed air system should be a priority in order to keep contaminants and other unwanted particles from passing through the system. Pneumatic system corrosion can equate to a loss of system efficiency and ultimately permanently damage your compressed air system. Our in-line SPG100 Pneumatic/Dryers are a great supplement to cleaning your compressed air just before the end use.

SPG100 W/Element SPG102

Inline Pneumatic Dryer Advantages

Dryer/Pneuguard® Oiler SPG903

Our Dryer/Pneuguard® Oiler ensures your shop tools are receiving clean, dry, air while delivering a continuous fine mist of lubrication. Mounted just ahead of your air tools this device accomplishes both tasks. Replacement elements (SPG102) are available.

Pneuguard® Oiler SPG201

Inline Pneumatic Dryer Advantages

To maintain the efficiency of the SPG units, it is recommended the elements should be changed every 30 days.

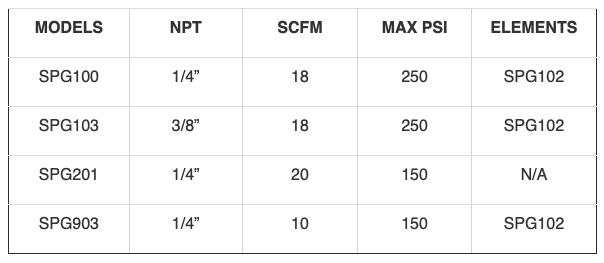

(Models: SPG100, SPG103, SPG201, SPG903)